„FORM FOLLOWS FUNCTION“

★ Design with metal - unlimited application possibilities

|

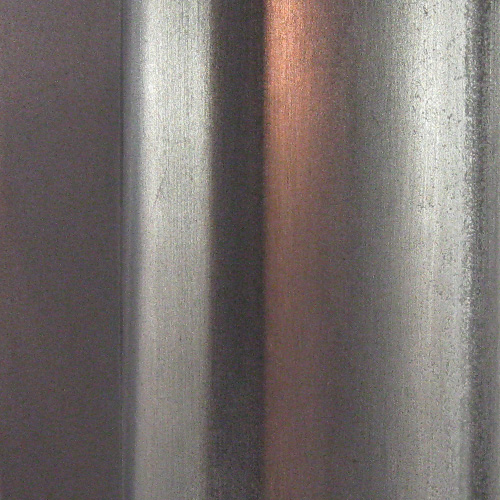

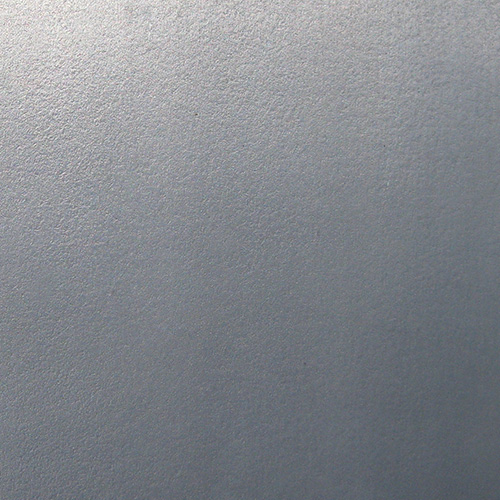

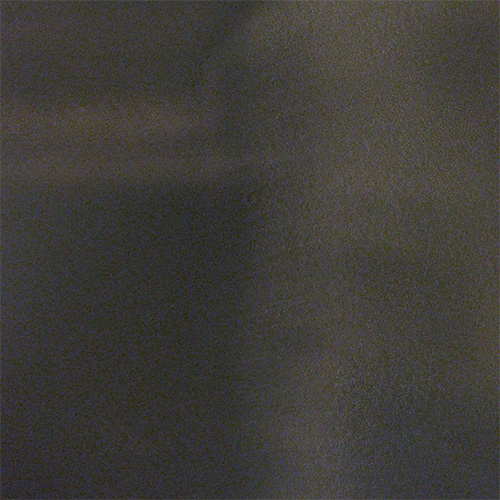

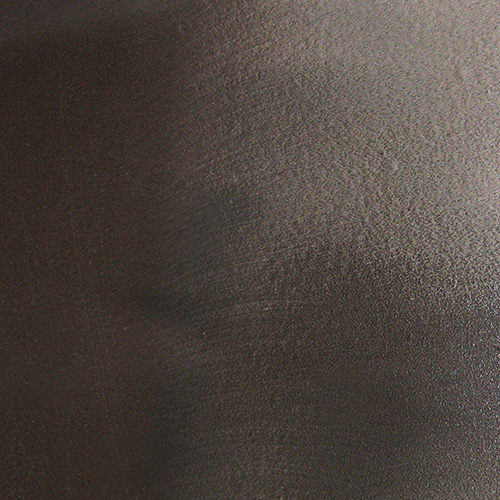

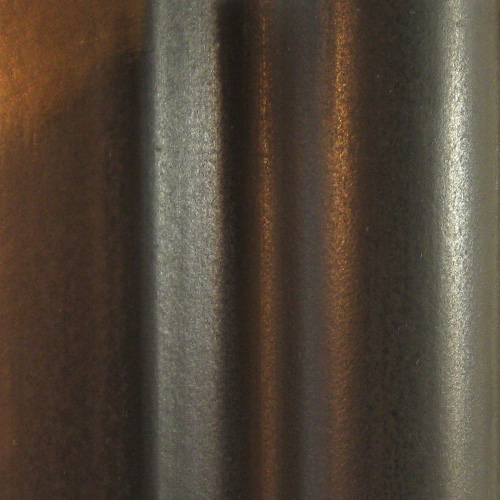

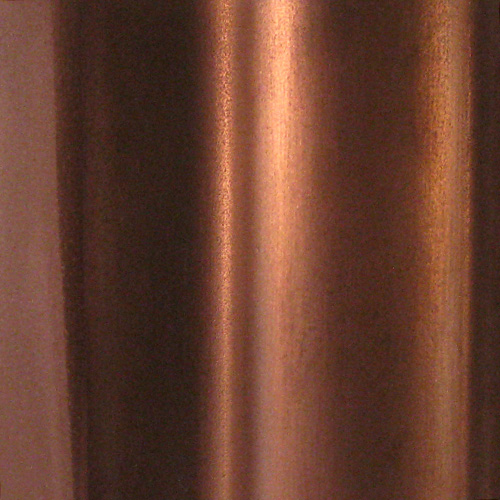

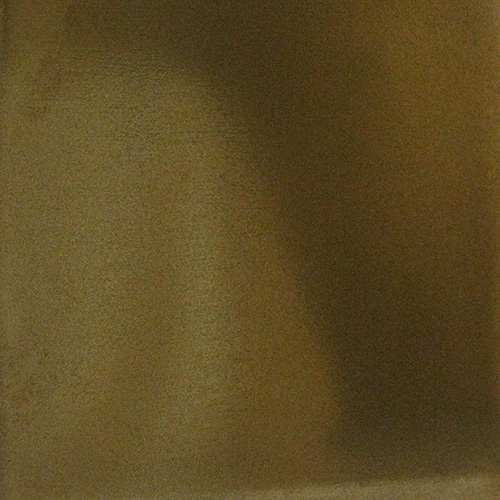

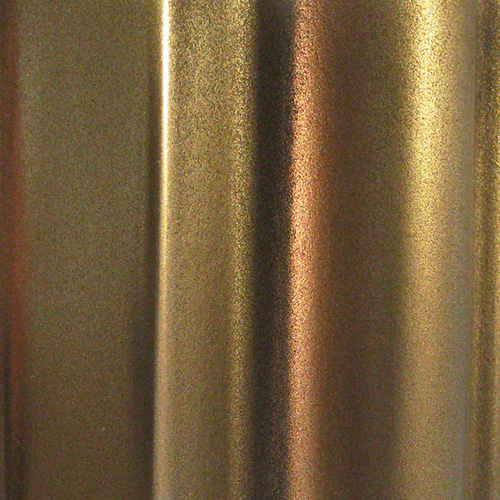

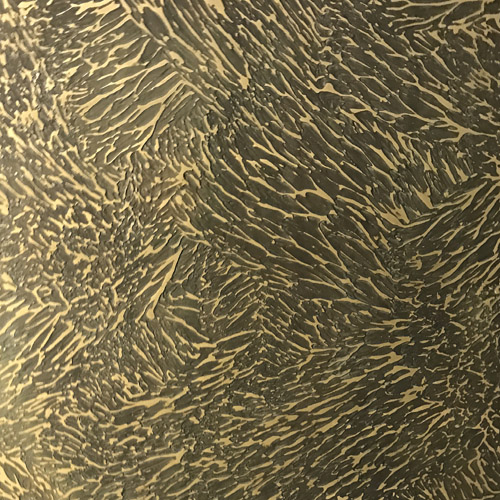

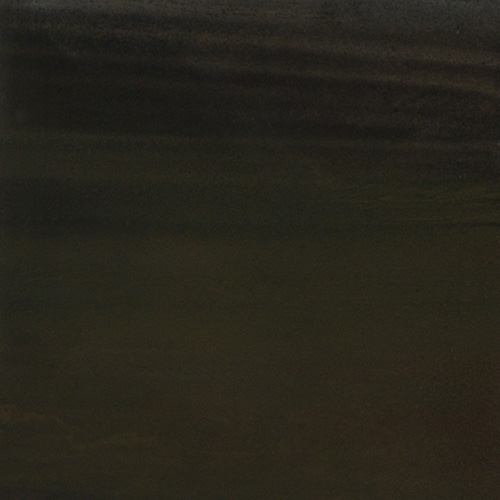

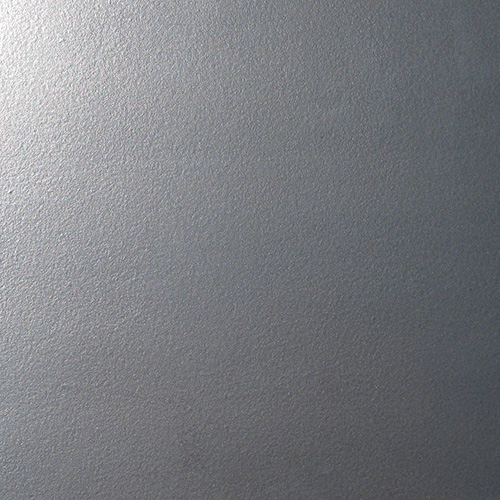

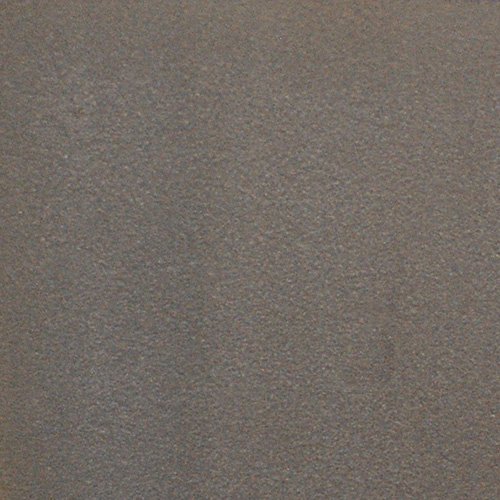

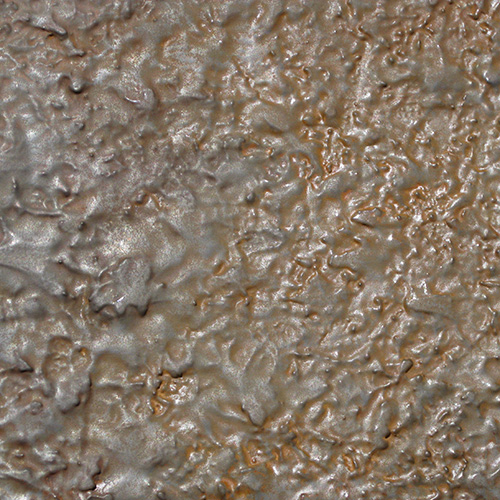

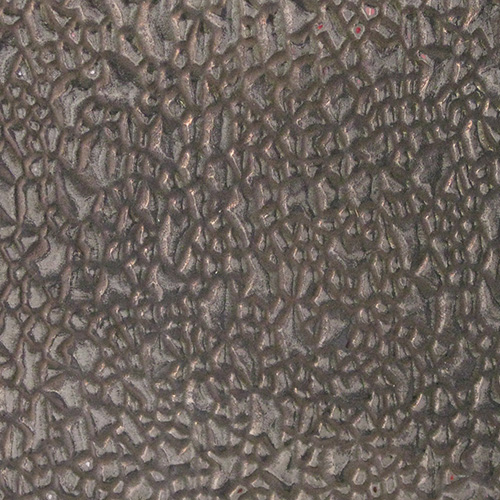

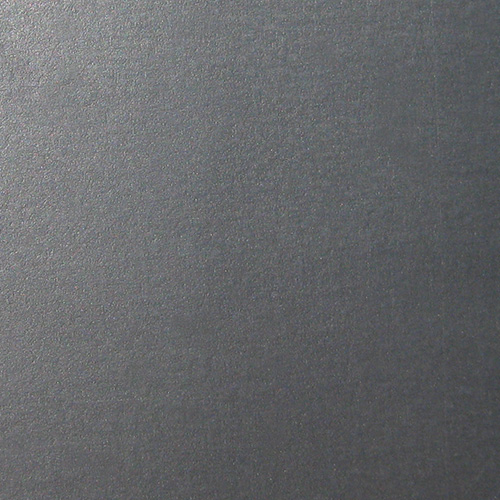

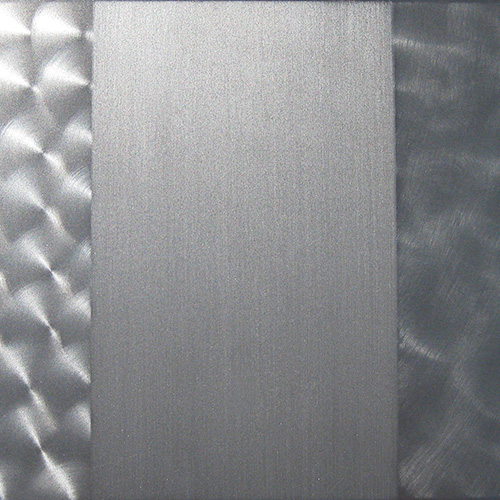

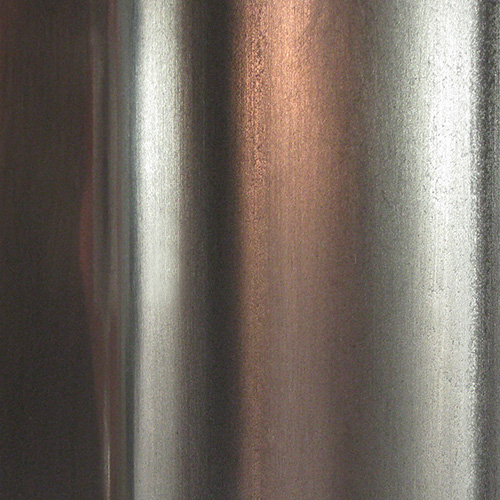

Metal has increasingly become an element of interior design. Whether in architecture, in living room design, in shop fitting, in industrial furniture or in the application for product design:

Metal is extremely versatile and stands for very high-quality appearances.

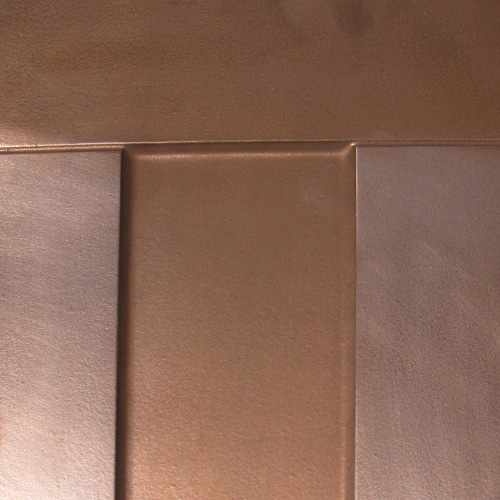

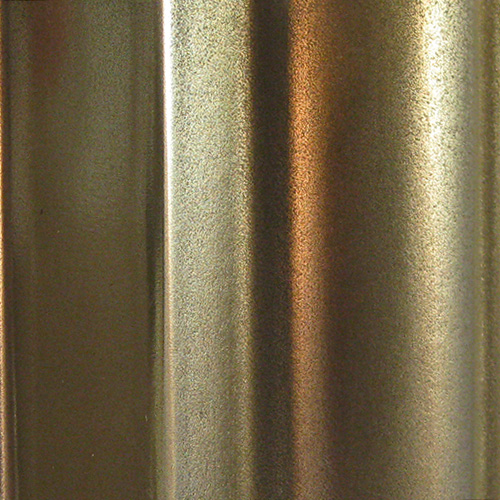

Metal application in the Barbican Shop // London

Metal application in the Barbican Shop // London

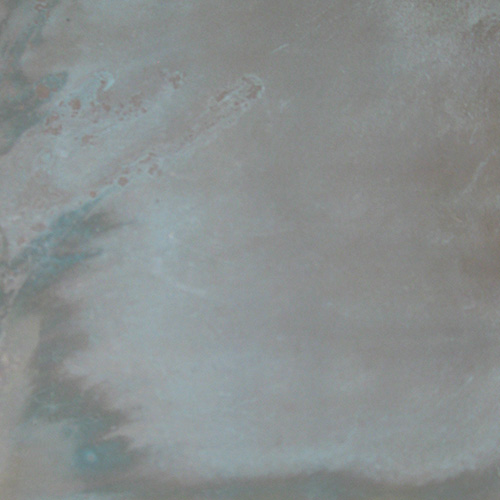

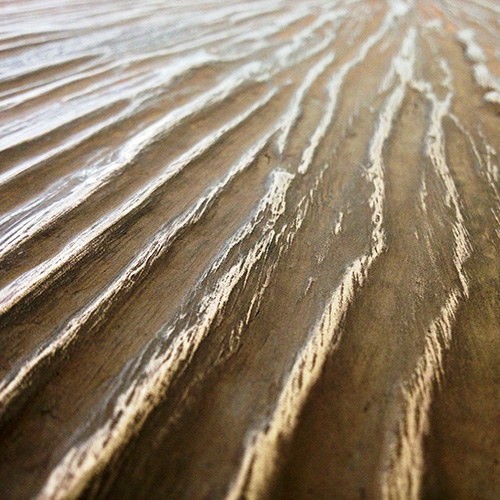

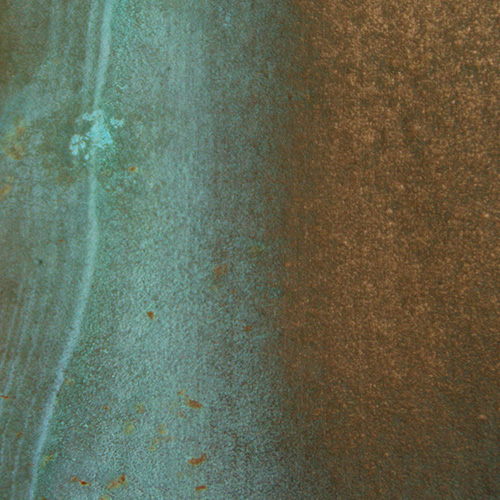

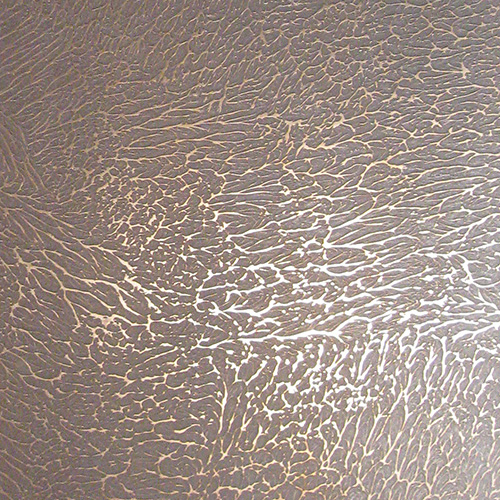

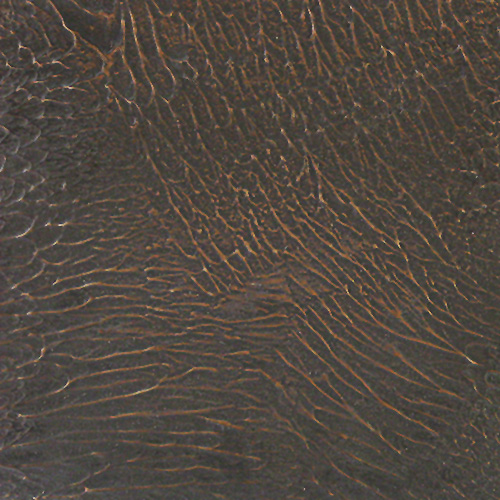

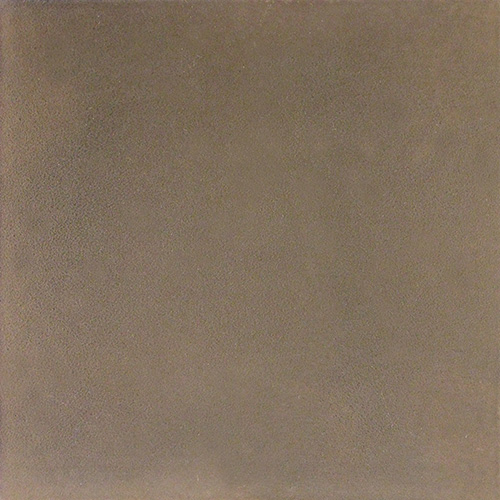

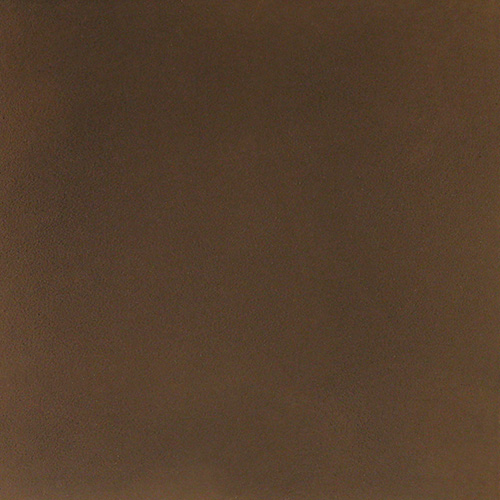

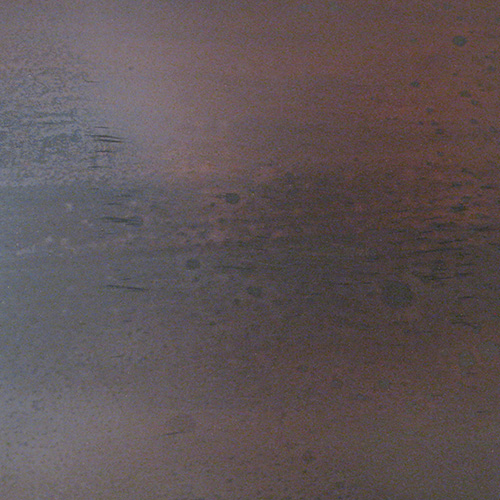

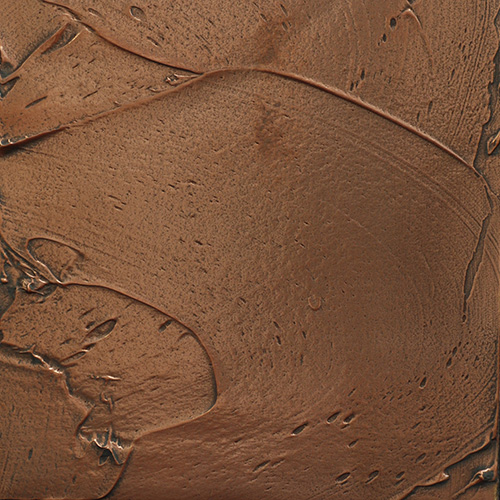

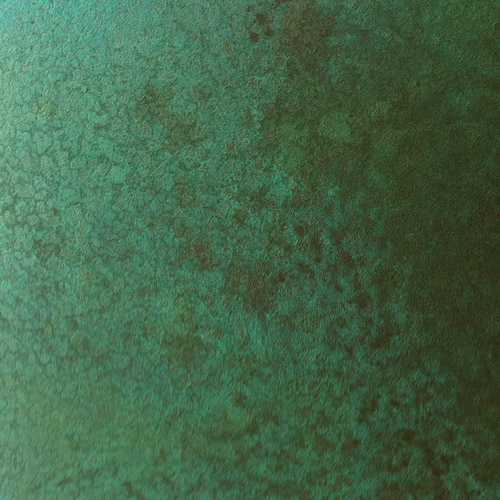

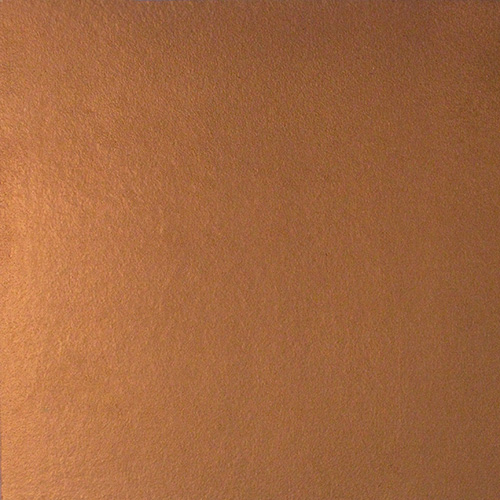

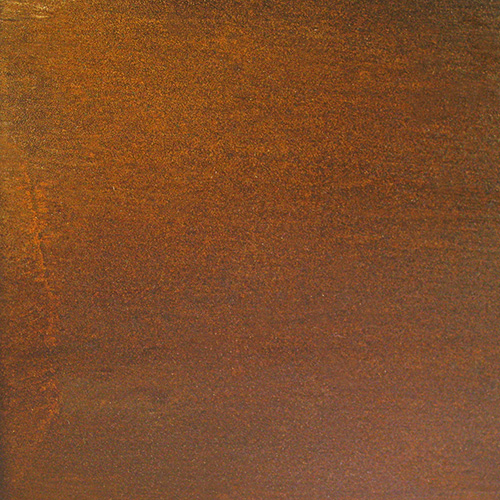

The metallized surfaces offer shop owners, interior decorators, architects, interior designers and industrial designers a variety of options for creative, individual designs. The sprayable metals can be processed seamlessly and are ideal for three-dimensional objects. Since the metallic coatings are suitable both for indoor and outdoor use, there are innumerable uses.

INNOMetal® GmbH produces real metal coatings, which consist of 95% metal powder. The liquid metals can be painted and filled and can be applied to almost any surface. After surface metallization, INNOMetal® has all the properties of cast metal, both visually and in terms of gloss and heat conduction.

We want to show you the creative possibilities metallizations offer, where they are already used, and hope that this page can be a source of inspiration for your imagination and creativity. The management of INNOMetal® has more than 30 years of experience in the field of chemistry and coatings. With new and optimized products, the success story is continuing.